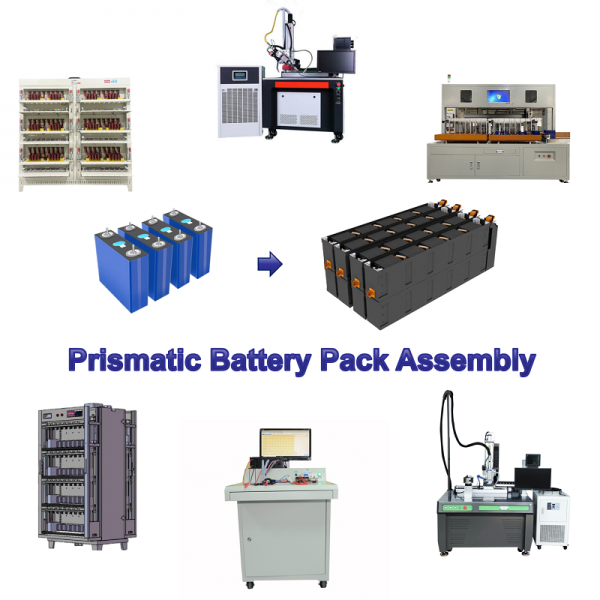

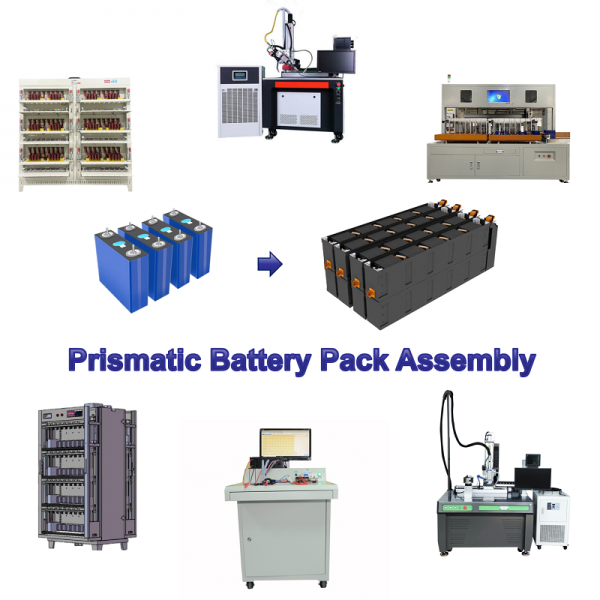

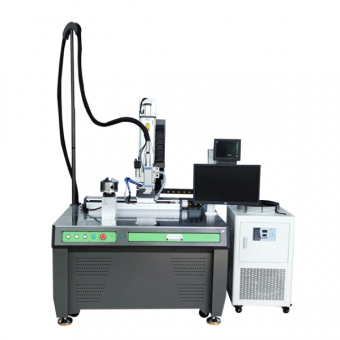

200W Pulse Laser Cleaning Machine for Prismatic Battery Cell Cleaning

Ⅰ、The principle of laser cleaning

Laser cleaning technology refers to the process of using a high-power density laser beam to irradiate the surface of a workpiece, causing the dirt, rust spots, or coatings on the surface to evaporate or peel off instantly, thereby achieving a clean and purified process. This cleaning equipment is a high-tech product for the new generation of surface treatment, which is easy to install, operate, and achieve automation. Easy to operate, simply turn on the power to perform cleaning without chemical reagents, media, dust, or water. It can remove resin, paint, oil stains, dirt, rust, coatings, coatings, and oxide layers from the surface of objects.

Ⅱ、The advantages of laser cleaning

1. Non contact cleaning, without damaging the substrate of the parts.

2. The laser cleaning head is lightweight and can be operated by hand for a long time

2. Accurate cleaning can achieve selective cleaning with precise position and size.

3. No need for any chemical cleaning solution, no consumables, safe and environmentally friendly.

4. Easy to operate, can be powered on, and can be automated for cleaning by hand or in conjunction with a robotic arm.

5. Red light assisted focusing, and the focusing position can be adjusted according to different field mirrors

6. High cleaning efficiency and time-saving.

7. The laser cleaning system is stable and requires almost no maintenance.

Ⅲ、The advantages of laser cleaning

|

Cleaning comparison

|

Chemical cleaning

|

Mechanical polishing

|

Dry ice cleaning

|

Ultrasonic cleaning

|

Laser cleaning

|

|

Cleaning method

|

Chemical cleaning agent cleaning

|

Mechanical/sandpaper contact type

|

Dry ice, non-contact

|

Cleaning agent, contact type

|

Laser, non-contact

|

|

Appearance of workpiece

|

Damaged

|

Damaged

|

No damage

|

No damage

|

No damage

|

|

Cleaning efficiency

|

Low

|

low

|

Middle

|

Middle

|

High

|

|

Cleaning effect

|

General, uneven

|

General, uneven

|

Excellent, uneven

|

Excellent, with a small scope

|

Excellent, high cleanliness

|

|

Cleaning accuracy

|

Uncontrollable, poor accuracy

|

Uncontrollable, poor accuracy

|

Uncontrollable, poor accuracy

|

Cleaning range cannot be specified

|

Accurate and controllable, with high precision

|

|

Cleaning consumables

|

Chemical cleaning agent

|

Sandpaper/grinding wheel/oilstone

|

dry ice

|

Special cleaning solution

|

Only requires power supply

|

|

Safety and environmental protection

|

Severe chemical pollution

|

Environmental pollution

|

Pollution-free

|

Pollution-free

|

Pollution-free

|

|

Technical Labor

|

High technical requirements, requiring protection

|

High strength, requiring protection

|

Simple, handheld or automated

|

Simple, but requires manual addition of consumables

|

Simple, handheld or integrated automation

|

|

Cost investment

|

Low initial investment and extremely high cost of consumables in the later stage

|

High initial investment and high labor costs for consumables in the later stage

|

Medium initial investment, high later consumables costs

|

Low initial investment, moderate later consumables costs

|

High initial investment, no consumables in the later stage, and extremely low maintenance costs

|

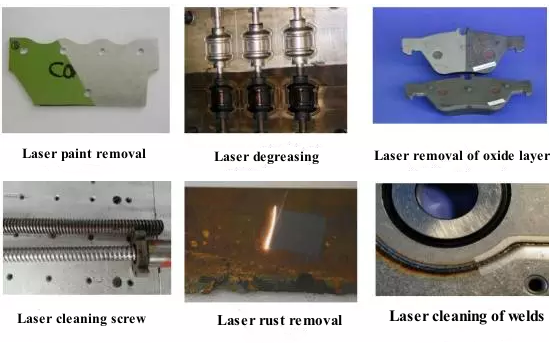

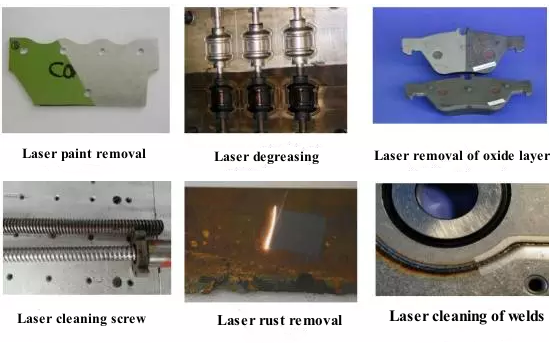

Ⅳ、Industry applications of laser cleaning

1. Aerospace industry: Laser cleaning of aluminum alloy before and after welding; Laser cleaning of titanium alloy before and after welding; Laser cleaning for repairing aircraft radar layers.

2. Ship manufacturing industry: laser cleaning before and after welding in ship manufacturing; Laser cleaning of the surface before painting; Ship maintenance and cultivation

3. Rail transit industry: stainless steel train manufacturing, laser cleaning; Laser cleaning for aluminum alloy train manufacturing; Maintenance and cultivation of rail transit equipment, laser cleaning

4. Automotive manufacturing industry: Laser cleaning of galvanized sheet before welding; Laser cleaning of aluminum alloy before and after welding

5. Steel manufacturing industry: laser rust removal on steel surfaces; Laser rust removal on the surface of cold-rolled sheet.

Ⅴ、Configuration

|

Configuration and model

|

TMAX-HY-L200-P

|

Remark

|

|

Fiber laser system

|

Pulse laser 200W (nanosecond)

|

TMAX

|

|

LASER

|

Handheld cleaning hair

|

TMAX

|

|

Laser head scanning system

|

High speed motor and drive

|

TMAX

|

|

Control card and software

|

Laser cleaning control card

|

TMAX

|

|

Wireless Controller

|

Remote wireless controller

|

TMAX

|

|

Control panel

|

Handheld

|

TMAX

|

|

Transformer

|

Voltage from 110V to 220V

|

|

Ⅵ、Main technical parameters

|

Model

|

TMAX-HY-L200-P

|

|

Wavelength

|

1064nm

|

|

Maximum laser output power

|

> 200

|

|

Frequency adjustable range

|

1 - 4000 kHZ

|

|

Maximum pulse energy

|

5MJ

|

|

Pulse width

|

2 - 500 NS

|

|

Beam Diameter

|

4.0±0.5,7.5±0.5(customizable)MM

|

|

Supply Voltage

|

48V

|

|

Settable working range

|

100mm

|

|

Weight

|

48kg

|

|

Machine size

|

1080*900*1480mm

|

|

Power consumption of the entire machine

|

1000W

|

Ⅶ、Detailed technical requirements:

|

Model

|

TMAX-HY-L200-P

|

|

Laser class

|

Class IV

|

|

Output power

|

200±3W

|

|

Wavelength

|

1064±3nm

|

|

Laser mode quality(M2)

|

<1.3

|

|

Laser power stability

|

±5  (Max) (Max)

|

|

Laser single pulse energy

|

5mj (max)

|

|

Laser power adjustment range

|

1 ~100 ~100

|

|

Laser frequency adjustment range

|

1~4000khz

|

|

Pulse width adjustment range

|

1~500ns

|

|

Cooling method

|

Forced air cooling

|

|

Cooling method

|

Spiral (10 levels adjustable)

|

|

Single cleaning size

|

Adjustable length of 1-150mm

|

|

Parameter adjustment method

|

Dual touch screen control system

|

|

Touch system size

|

7 inches+4 inches

|

|

Fiber Length

|

Standard configuration of 5 meters

|

|

Input power supply

|

AC220V±10  ,50/60Hz ,50/60Hz

|

|

Overall Power Consumption

|

800W

|

|

Equipment structure

|

Workbench

|

|

Work environment

|

0—40℃,≤70  RH RH

|

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported