Waste Lithium Battery Recovery Plant PCB board Recycling Equipment

Introduction

Function: Separate scrap PCB board into pure copper and resin powder. Before process PCB board need use the heating machine separate the electric parts away from the board because the boards including some valuable metals can be gain by some kind of chemical.

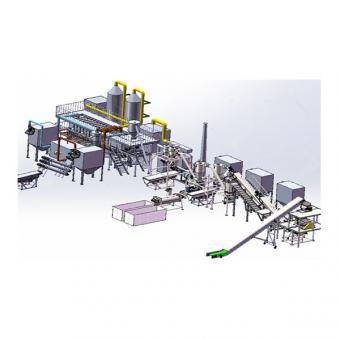

Overview of equipment: The equipment for disassembling electronic components of printed circuit boards is mainly used for disassembling electronic components of discarded televisions, recorders, computers, electronic equipment, and other printed circuit boards, as well as specialized equipment for solder recycling. The equipment mainly consists of heating furnace body, mesh belt conveyor system, inlet and outlet workbenches, contact impact system, blowing system, electronic components, solder sorting and recycling device, circuit board fixture, electric control system, and other main components.

Equipment characteristics: The equipment can operate continuously, with high disassembly efficiency, and can automatically sort and recycle electronic components and solder from discarded circuit boards in one go; The electronic components are undamaged after disassembly and can continue to be used, extending their service life and increasing profit margins.

1. The disassembly process has a high degree of automation, reduces labor intensity, and saves manpower and time;

2. Adopting hot air circulation heating method, the furnace temperature uniformity is good;

3. Temperature controllable and fully functional;

4. The running speed of the conveyor system belt is continuously adjustable;

5. The equipment operates stably and reliably, and is easy to operate, use, and maintain;

6. Adopting an integrated structure of electrical control and furnace body, it effectively utilizes spatial location, occupies a small area, has a reasonable and compact equipment structure layout, and has a beautiful and elegant appearance design;

7. The discharged waste gas is centrally treated, and adsorbed and filtered to meet environmental standards.

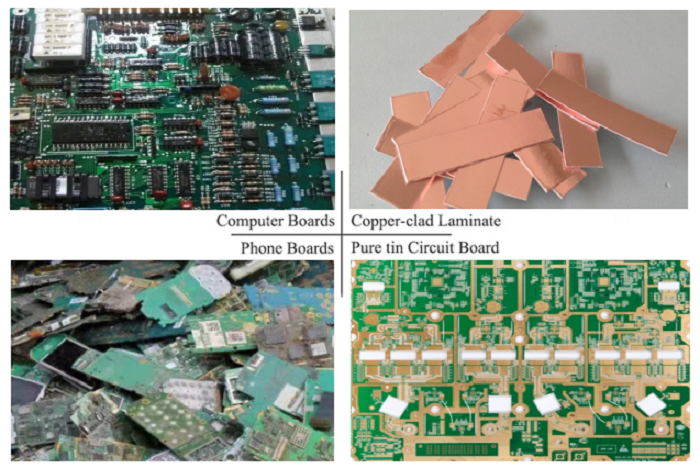

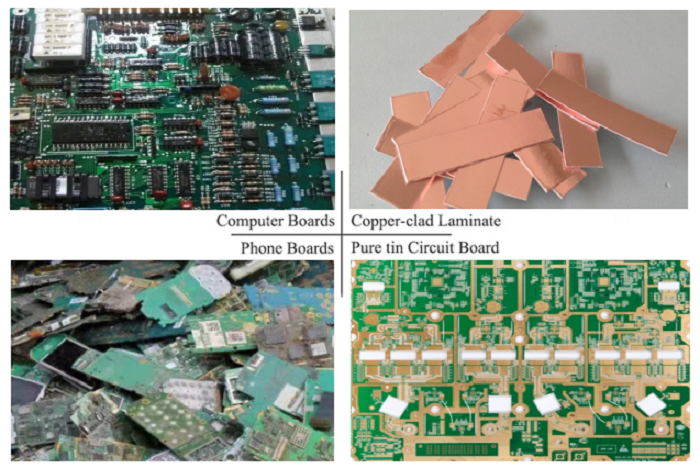

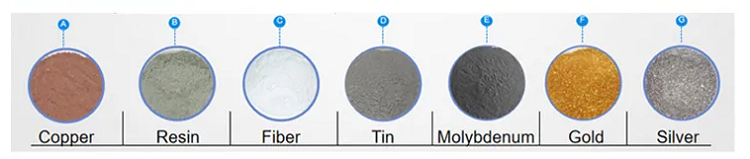

Raw Material

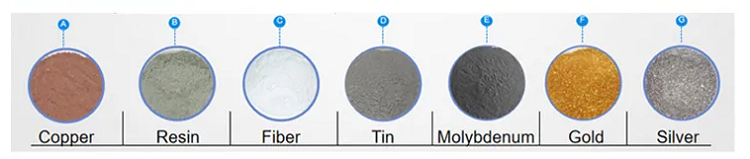

Final Products

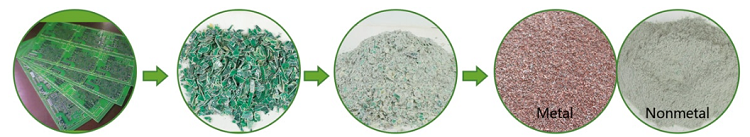

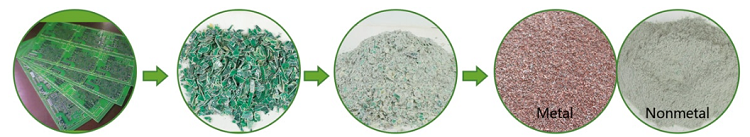

Working Process

The waste circuit board recycling equipment adopts a dual axis shredder for the first crusher, a hammer crusher for the second crusher, and a high-speed turbine crusher for the third crusher. The material is crushed into powder through three-stage crushing, and then sorted by airflow sorting equipment and electrostatic sorting equipment. This production line has a novel and unique structure; Large production capacity and low power consumption; One feeding, multi machine collaboration completion; The entire production line is controlled by PLC. The successful development of this machine not only improves the quality of reused copper, but also prevents secondary pollution. The recycling rate of copper in waste circuit boards can reach over 99% through separation and sorting equipment. The regeneration processing of waste circuit boards adopts primary tearing, secondary crushing, and tertiary crushing to form a mixture of metal and resin fiber powder; Then, a process route is used to separate the metal and resin through wind and electrostatic separation. To prevent dust pollution during the processing, a bag dust removal device was added after the wind sorting process, effectively solving the problem of dust pollution.

Product display

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported