Prismatic Cell Assembly Plant: A Comprehensive Overview

A prismatic cell assembly plant is a specialized facility focused on the manufacturing of prismatic lithium-ion cells. These cells, characterized by their rectangular shape, are widely used in applications such as electric vehicles (EVs), consumer electronics, and energy storage systems due to their high energy density and efficient space utilization.

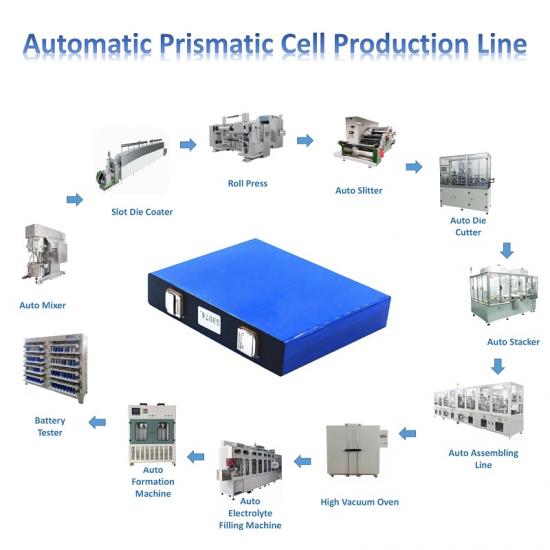

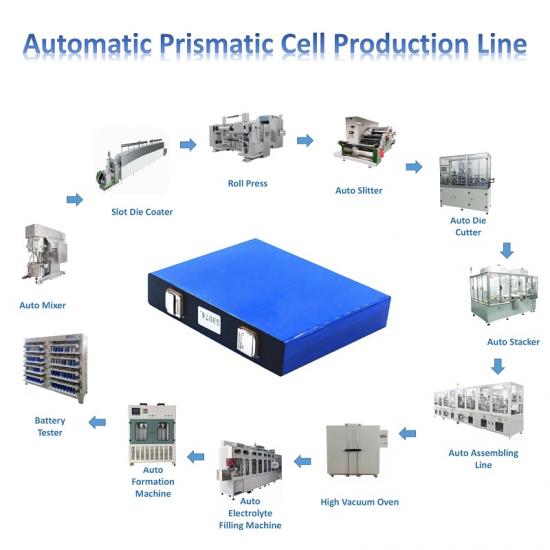

● Key Components of a Prismatic Cell Assembly Plant

1. Material Preparation

- Active Material Production: The anode (typically graphite) and cathode (lithium compounds) materials are prepared, often including binders and conductive additives.

- Separator Manufacturing: Separators made from materials like polyethylene or polypropylene are produced to prevent short circuits between electrodes.

2. Electrode Fabrication

- Coating: The electrode slurry is coated onto metal foils (aluminum for cathodes and copper for anodes) using precision coating machines.

- Drying: Coated electrodes are dried to remove solvents and achieve the desired performance characteristics.

- Calendering: The dried electrodes are compressed to enhance density, which improves electrical conductivity.

3. Electrode Cutting and Shaping

- The dried and processed electrodes are cut into specific dimensions tailored for prismatic cell design, ensuring precise layering during assembly.

4. Cell Assembly Line

- Layer Stacking: The anode, separator, and cathode are stacked together in the correct order, or alternatively, wound in certain designs.

- Electrolyte Filling: The electrolyte is injected into the assembled stack to saturate the electrodes and facilitate ion transport.

- Sealing: The assembly is sealed within a prismatic metal casing, which is crucial for preventing leakage and contamination.

5. Formation and Aging

- Formation Cycling: Initial charge and discharge cycles are performed to activate the materials and stabilize performance.

- Aging: Cells are aged in controlled environments to ensure consistent long-term performance.

6. Testing and Quality Control

- Performance Testing: Each prismatic cell is tested for capacity, voltage, internal resistance, and cycle life to ensure they meet specifications.

- Safety Testing: Rigorous tests for thermal stability, overcharging, and short-circuit resistance are conducted to ensure compliance with safety standards.

7. Packaging and Shipping

- Approved cells are packaged for shipment to customers or for integration into battery packs.

● Advantages of Prismatic Cells

1. Space Efficiency: Prismatic cells can be tightly packed in battery modules, optimizing space utilization in applications like EVs and energy storage systems.

2. Higher Energy Density: The design allows for more active material, enhancing the overall energy density compared to cylindrical cells.

3. Thermal Management: The flat design facilitates effective heat dissipation, improving safety and performance during operation.

4. Customization: Prismatic cells can be produced in various shapes and sizes, allowing for tailored solutions for specific applications.

● Applications of Prismatic Cells

- Electric Vehicles (EVs): Used extensively in battery packs for EVs due to their efficiency and space-saving design.

- Consumer Electronics: Found in laptops, tablets, and smartphones, where size and energy density are critical.

- Energy Storage Systems: Employed in grid storage solutions, solar energy systems, and backup power applications.

● Considerations for Prismatic Cell Production Equipment

1. Environmental Control: The assembly area must maintain strict humidity and temperature controls to prevent contamination and ensure consistent quality.

2. Material Compatibility: The selection of active materials and electrolytes must be compatible to ensure optimal performance and safety.

3. Automation: High levels of automation can enhance efficiency and reduce labor costs but require skilled personnel for operation and maintenance.

● Conclusion

A prismatic cell assembly plant is essential for producing high-performance lithium-ion batteries that meet the growing demands of various industries. As technology advances and the demand for sustainable energy solutions increases, prismatic cells are poised to play a significant role in the future of energy storage. Continuous improvements in manufacturing processes and equipment will be crucial to enhance efficiency, quality, and safety in prismatic cell production.

de

de en

en fr

fr ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6-Netzwerk unterstützt

IPv6-Netzwerk unterstützt